Fascination About Glass Infill Panels

Table of ContentsThe smart Trick of Glass Infill Panels That Nobody is DiscussingThe 6-Minute Rule for Glass Infill Panels

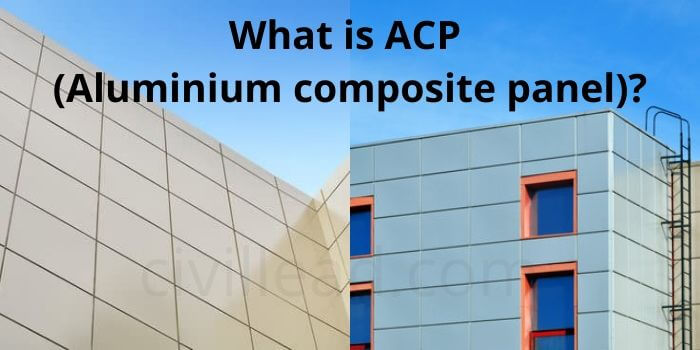

ACP has been used as a light-weight but very durable product in building and construction, specifically for transient frameworks like trade program cubicles as well as comparable temporary aspects. It has actually lately additionally been taken on as a support product for installing art photography, usually with an acrylic coating making use of procedures like Diasec or other face-mounting methods. ACP material has been made use of in famous structures as Spaceship Planet, Van, Dusen Arboretum, the Leipzig branch of the German National Collection. These frameworks made ideal usage of ACP with its expense, resilience, as well as effectiveness. Its adaptability, low weight, and also very easy forming and also refining enable ingenious style with increased rigidness and toughness.

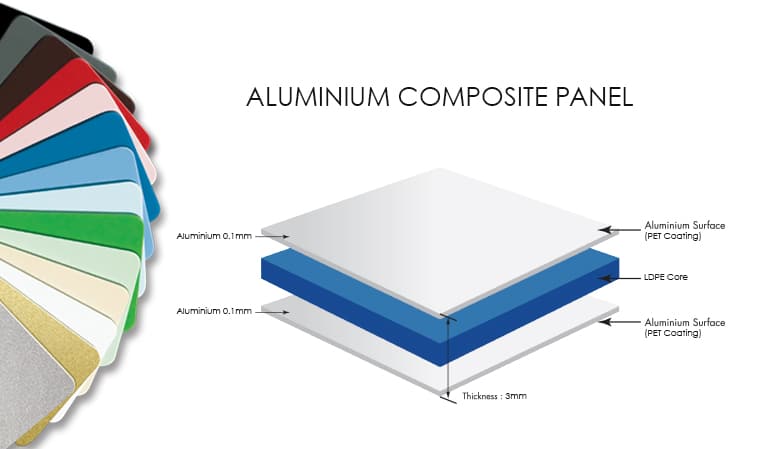

The standard ACP core is polyethylene (PE) or polyurethane (PU). These products do not have excellent fire-resistant (FR) properties unless particularly dealt with as well as are for that reason not generally ideal as a building material for houses; a number of territories have actually prohibited their use entirely. Arconic, proprietor of the Reynobond brand, warns the potential purchaser. Concerning the core, it says that range of the panel from the ground is a determinant of "which products are more secure to use". In a sales brochure it has a graphic of a structure in flames, with the inscription" [a] s soon as the structure is higher than the firemans' ladders, it has to be developed with an incombustible material".

70% mineral core) from there to approximately c. 30 meters, the height of the ladder; and also the European A2-rated product (c. 90% mineral core) for anything over that. In this brochure, Fire Security in Skyscraper: Our Fire Solutions, item specification is only given for the last 2 products. The cladding products, especially the core, have been linked as a feasible contributing factor in the 2017 Grenfell Tower fire in London, in addition to in skyscraper fires in Melbourne, Australia; France; the United Arab Emirates; South Korea; and the USA. Fire-rated cores, such as mineral woollen (MW), are an alternative, but are usually a lot more costly as well as frequently not a lawful need.

The Buzz on Glass Infill Panels

Aluminium can be repainted in any kind of type of colour, and ACPs are produced in a wide array of metal and also non-metallic colours in addition to patterns that copy various other materials, such as wood or marble. The core is frequently low-density polyethylene (PE), or a mix of low-density polyethylene as well as mineral material to display fire retardant residential or commercial properties. 3A Composites (formerly Alcan Composites & Alusuisse) invented aluminium composites in 1964 - as a joint development with BASF- as well as commercial manufacturing of Alucobond commenced in 1969. The product was patented in 1971, a patent which expired in 1991. After the expiry of the patent a number of business started industrial production such as Reynobond (1991 ), Alpolic (Mitsubishi Chemicals, 1995), etalbond (1995 ).

Sandwich panel building techniques have experienced considerable useful link development in the last 40 years. Formerly, sandwich panels were thought about items suitable just for functional building and constructions and also industrial structures. However, their good insulation attributes, their convenience, top quality and also attractive aesthetic appearance, have resulted in a growing as well as extensive use the panels throughout a massive variety of buildings. Sandwich panels call for the CE mark to be sold in Europe. The click to read European sandwich panel standard is EN14509:2013 Independent double-skin metal-faced insulating-panels - Factory-made items Requirements. Sandwich panels top quality can be licensed by using the top quality degree EPAQ The top qualities that have actually created the quick development in using sandwich panels, specifically in construction, consist of: Sandwich panels have -worths from 0.

05 W/( m, K) for mineral wool. For that reason, they can accomplish different U-values depending on the core and also the density of the panel. The installation of a system with sandwich panels reduces thermal bridges with the joints. The analyzed audio reduction measurement exists at approx. 25 d, B for PU aspects as well as at approx. 30 d, B for MW aspects. The area between the assistances can be as much as 11 m (wall surfaces), relying on the type of panel used. Regular applications have areas between the assistances that are approx. 3 m pop over to this site 5 m. The thickness of panels is from 40 mm up to greater than 200 mm.

All these geometric as well as material residential or commercial properties influence the global/local failing behavior of the sandwich panels under different loading problems such as imprint, impact, tiredness as well as bending. Sandwich panels have different fire behaviours, resistance and reaction, depending on: the foam, the metal thickness, the finish, and so on. The customer will need to pick in between the different sandwich panel kinds, depending upon the requirements. Research study by the Association of British Insurance Providers as well as the Building Research Study Establishment in the UK highlighted that "sandwich panels do not begin a fire by themselves, and also where these systems have been linked in fire spread, the fire has typically started in high risk areas such as cooking locations, consequently spreading out as a result of inadequate fire risk administration, prevention and also control actions" (glass infill panels).